How Decision One Systems Can Help

- Home

- Why Decision One

- How Decision One Systems Can Help you Excel

Planning, Communication and Control in the execution of orders from initial confirmation through to shipment

Increased Performance on Delivery Performance %

You can achieve the above key performance indicator and it is directly related with Planning. So it is necessary to :

- Plan effectively, including rapid response to changing requirements

- Constantly Communicate the latest plan, including new priorities

- Update and Review Progress

- Quickly identify problems

- Re-Plan when targets are not met

This sounds obvious, but as we all know, there are many variables that affect on-time delivery including:

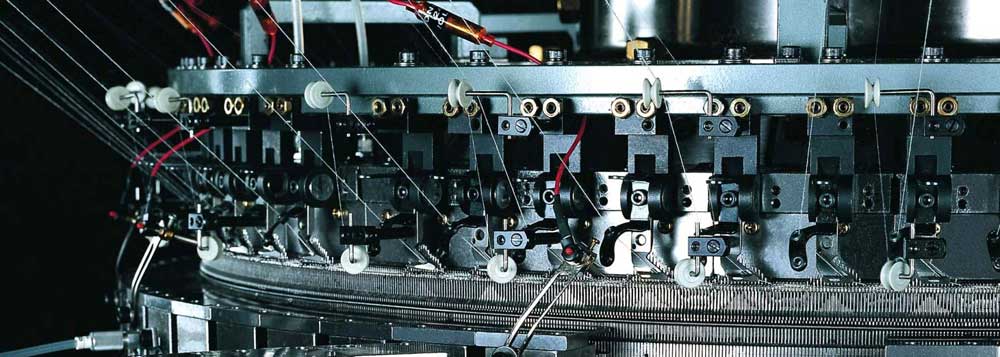

- Primary Bottle Neck capacity (Sewing)

- Secondary Capacity (e.g. Cutting, Embroidery, Washing, Special Machines)

- Pre-production Critical Path

- Raw materials availability

A change in any one of these will always cause a knock on effect, such that one change could cause many changes. Decision One Systems has been specifically developed for the Apparel and Textile Industry to help you plan quickly and have a clear picture of the status of all orders in your business.

Knock on effects in any area of the plan are calculated and priorities and problems rapidly identified.

The end result is that key decision makers do not waste time calculating or searching for information, but instead can quickly focus on the problems, then identify and test alternative solutions. The End result … Better Performance!

Reduced Prices Better Value

To reduce prices, you need a more efficient business. Production Efficiency is a key cost driver and good factory efficiently starts with good planning.

The three key ways Decision One Systems can help increase factory floor efficiency and therefore reduce production cost are:

- The Integrated approach to raw material and pre-production (Critical path) Planning in Decision One Systems, helps to reduce production stoppages or waiting time on the factory floor, due either to raw materials shortages or delays, or lack of coordination in pre-production activities

- Highly visual and easy to use, detailed planning boards allow planners to build an accurate and achievable plan quickly, improve use of available capacity and minimize unnecessary style changes. Potential bottle neck areas can be identified in advance (e.g. cutting, printing, embroidery or special machine constraints)

Rapid 'What-if' modeling through (Plan Viewers) allows alternative solutions to be tested, then accurate plans to be communicated to all departments. A better Plan = Smoother Production and less ‘fire-fighting’ on the factory floor - Decision One Systems replaces many manual forms of planning (eg. Spread Sheets, Word documents, emails, meetings, Telephone calls).

A better plan can be achieved and communicated with fewer resources, thus reduces overhead costs. Better use can be made of limited, skilled management resources, such as IE & Production Management, who no longer need to waste time on “number crunching”. Decision One Systems allows them to see problems sooner and spend more time solving them.

Reduction in Lead-Time

For many businesses, current planning practices present a major barrier to speed and flexibility. Most companies still use numerous spread sheets systems, particularly in the area of planning and merchandising. Each person retains control of his or her own separate spreadsheet environment and so coordination of information requires laborious, manual intervention.

This approach creates many delays, risk of errors and lack of visibility. As evidence of this, progress meetings are typically many hours long, with much of this time spent working through paper documents, chasing an accurate picture of the current situation.

Decision One Systems brings visibility, coordination and control, through a single integrated system, which works with your existing core systems, thereby significantly reducing or eliminating the need of spreadsheets and time consuming meetings/telephone calls/emails to communicate the frequent changes.

Decision One systems uses dynamic critical path linking so T&A targets can be pushed (ASAP) from an order receipt date or pulled (JIT) from Cut Start, Sew Start, Delivery dates etc. Changes to the plan immediately change critical path and raw material priorities and highlight any potential problems clearly on the planning board. Exception reports also clearly highlight any problems.

In practice this means staff always have clear priorities based on latest plan and can work to standard operating procedures (SOP), but still have the flexibility to manage special situations on a case-by case basis.

A complete record can be kept for each order with completion dates, user notes and the ability to enter reasons for failure and lateness. The data can then be analyzed to help measure performance against targets and identify problem areas where lead times have not been achieved or areas where further lead time reductions are possible.

Key Features

Subscribe

Please subscribe to our mailing list for technology and business updates

We hereby promise to be responsible emailers.